Capabilities

Laser Cutting & Tube Profiling

12kW Laser

Many companies require metal components, whether for production-scale manufacturing or project-specific builds. They are looking for a reliable metal work partner who offers innovative ideas and efficient production processes. L&N Metal Works understands the need for advanced fabrication services, especially in today’s fast-paced, competitive business environment. Our full-service metal fabrication shop is equipped with machinery, including a 12kW laser. The 12kW laser enables us to efficiently cut metal sheets, providing clients with consistent quality and precision every time.

Capabilities of the 12kW Plate Laser

Our 12kW laser cutter delivers the precision, reliability, and speed to efficiently process sheets with flawless results.

L&N Metal Works’ 12kW laser specializes in cutting:

- Aluminum and stainless steel up to 1 ½” thick

- Carbon steel up to 1 ¾” thick

- Sheet sizes up to 80” x 160”

Contact Us Today for a Quote

Whether your team is working on a complex project or needs simple cuts, L&N Metal Works offers precision cutting capabilities. The 12kW laser produces clean, accurate edges with minimal material waste. Contact us today to learn more about our 12kW laser cutting services. From raw material to refined result – we make metal work. Request a quote today.

20kW Laser

Companies working with heavy-duty metal components often lack the advanced metal fabrication machinery to handle their most demanding projects. Cutting through the toughest materials is a challenge without the power and capacity of equipment like the 20kW laser. L&N Metal Works understands the need for advanced fabrication services for heavy-duty projects. In 2024, we expanded our metal fabrication facility to improve our ability to cut large, thick metal sheets. Our full-service metal fabrication shop is equipped with state-of-the-art machinery, including a 20kW laser. The 20kW laser enables us to handle large-scale industrial projects efficiently and cost-effectively. Clients rely on L&N Metal Works to laser cut their toughest materials, and we deliver the speed, precision, and quality they expect every time.

Capabilities of the 20kW Plate Laser

Our 20kW laser cutter pushes the boundaries of power and precision, offering exceptional cutting capabilities.

L&N Metal Works’ 20kW laser is designed to cut through even the toughest materials with ease:

- Aluminum and stainless steel up to 2” thick

- Carbon steel up to 2 ⅜” thick

- Sheet sizes up to 80” x 160”

Contact Us Today for a Quote

With its exceptional power and large bed size, L&N Metal Works’ 20kW laser cuts large sheets in a single pass, easily handling heavy-duty components. Contact us today to learn more about our 20kW laser cutting services. From raw material to refined result – we make metal work. Request a quote today.

Tube Laser

Many companies need metal components, like handrails, pipes, beams, tubes, and square bars, cut to exact specifications. Yet cutting the metal manually, in-house takes time. Many shops don’t have advanced fabrication tools to laser-cut metal with a profile. L&N Metal Works does! L&N Metal Works uses its 3kW tube laser to precisely cut metal with a profile, so companies have the metal components they need to be productive and profitable.

Capabilities of the 3kW Tube Laser

Our 3kW tube laser can handle everything from intricate custom profiles to large-scale production runs. L&N Metal Works state-of-the-art 3kW tube laser delivers unparalleled precision and versatility across a wide range of materials and profiles.

L&N Metal Works’ 3kW tube laser is capable of cutting aluminum, carbon steel, and stainless steel and shapes up to 9″ diameter profile, including:

- Profiles from 3/4” to 9” diameter

- Lengths up to 24’

- Shapes (angle, C channel, W beams, pipe)

- Tubing (square, rectangular, round, custom profiles)

Contact Us Today for a Quote

With the ability to cut a variety of materials and shapes, L&N Metal Works’ tube laser precisely cuts a broad range of metal components. Contact us today to learn more about our tube laser cutting services. From raw material to refined result – we make metal work. Request a quote today.

CNC Bending & Tube Forming

245 Ton CNC Press Brake

The possibilities are endless when it comes to bending and forming metal sheets into 3D shapes. From tiny, intricate metal parts for the automotive aftermarket industry to large, structural components for infrastructure projects, a CNC Press Brake bends and forms metal components with precision and consistency. Not every company has the advanced metal-forming machinery they need to complete projects in-house. That’s why they rely on metal fabricators like L&N Metal Works. L&N Metal Works operates a full-service fabrication shop equipped with advanced machinery, including two high-capacity CNC press brakes. Our 245-ton, 13-foot 4-axis and 9-axis press brakes deliver precise forming for complex parts and heavy-gauge materials. The 9-axis model features sheet followers for safe, efficient handling of large panels during bending—ensuring accuracy and consistency across every run.

Our powerful 245-Ton x 13’ CNC Press Brakes enable us to achieve precise bends over long lengths, so our clients have the metal components that their projects demand.

Capabilities of the 245-Ton x 13’ CNC Press Brake

A 245-Ton x 13’ CNC Press Brake delivers precise programming of bends, angles, and sequences, ensuring consistency across large production runs.

L&N Metal Works’ 245-Ton x 13’ CNC Press Brakes are engineered to handle a wide range of materials and thicknesses, providing the force and control needed to achieve precise bends over long lengths:

- Maximum Force: 245 tons of bending power

- Length Capacity: Handles materials up to 13 ft. in length

- Consistent Bending: CNC technology ensures every bend is accurate and repeatable, reducing errors and material waste

- Materials: Bends and forms steel, aluminum, and stainless steel

Contact Us Today for a Quote

With a capacity of 245 tons and 13 ft. length, our CNC Press Brake handles heavy-duty components with ease. Contact us today to learn more about our 245-Ton x 13’ CNC Press Brakes. From raw material to refined result – we make metal work. Request a quote today.

CNC Tube Bending

Bending metal tubing into complex shapes isn’t easy. Metal fabrication requires a certain finesse to meet precise tolerances. Not every machine shop is equipped with the advanced fabrication machinery and skilled technicians to bend metal tubing to precise requirements. L&N Metal Works has the CNC Tube Bending technology to fabricate even the most complex metal components. Our CNC Tube Bending machinery achieves smooth angles and curves to ensure structural strength. Our partners rely on our on-time, high-quality CNC Tube Bending services for their success.

Capabilities of CNC Tube Bending

L&N Metal Works’ CNC Tube Bending is a cost-effective service for everything from standard bends to complex, custom profiles. L&N Metal Works CNC Tube Bending capabilities include:

- Pipe Bending Capacity: Bending up to 2” Schedule 40 pipe with precision and consistency.

- CNC Precision: Computer-controlled bending ensures that each bend is accurate and repeatable, reducing errors and material waste.

- Complex Geometries: Capable of creating complex shapes and bends with tight radii, our CNC bender is ideal for intricate designs and tight tolerance requirements.

- Large Stock of Tubing & Pipes: Our inventory includes round, solid, square, and rectangular tubes in aluminum, carbon steel, and stainless steel.

Contact Us Today for a Quote

Specializing in bending tubes for structural components and hydraulic assemblies, L & N Metal Works Tube Bending machinery achieves the smooth angles and curves you need. Contact us today to learn more about our CNC Tube Bending services. From raw material to refined result – we make metal work. Request a quote today.

Welding & Joining

Laser Welder

Traditional MIG and TIG welding can be expensive, time-consuming and labor intensive. Plus, these welding methods carry the risk of material distortion. Laser welding is 10 times faster than MIG welding and 40 times faster than TIG welding. Additionally, a laser welder’s low-heat technology leaves a flawless finish with minimal distortion. While traditional welding has its place, state-of-the-art laser welding often is the preferred alternative. Yet not every company owns a high-tech laser welder or employs an AWS certified welder. L&N Metal Works does! L&N Metal Works goes the extra mile with its laser welder services. We help clients meet their most demanding challenges, comply with critical lead times, and achieve success.

Capabilities of the Laser Welder

Our laser welder is designed to deliver precise, high-quality welds across a range of materials and applications. Key features of L&N Metal Works’ laser welder include:

- Unmatched Precision: The laser welder uses focused laser beams to achieve incredibly precise welds, ideal for intricate and delicate components.

- Versatile Material Handling: Capable of welding a wide variety of materials, including metals like steel, stainless steel, aluminum, and more, making it suitable for diverse industrial applications.

- Minimal Distortion: The laser welding process reduces thermal distortion, ensuring that your components retain their original shape and properties, even after welding.

Contact Us Today for a Quote

Offering repeatable, defect-free results, L&N Metal Works’ laser welder is the preferred welding method for fine detail work. L&N Metal Works’ laser welding services and AWS certified welder are here to meet your needs. Contact us today to learn more about our laser welder. From raw material to refined result – we make metal work. Request a quote today.

MIG and TIG Welding

Many companies need metal components engineered, laser cut, bent, formed, and welded to exacting standards. Yet performing advanced metal fabrication in-house just isn’t feasible. They need a production partner with the expertise and equipment to complete a wide range of metal fabrication processes. For convenience and cost-effectiveness, they partner L&N Metal Works, of Gillett, Wisconsin. L&N Metal Works is a one-stop machine shop for metal fabrication all under one roof. Our AWS certified welders ensure that each project receives the precision and craftsmanship it deserves. Our MIG and TIG welding services provide the quality necessary for quality carbon steel, aluminum or stainless steel fabrication.

Capabilities of MIG and TIG Welding

L&N Metal Works is proficient in both MIG and TIG welding techniques, allowing us to provide the best welding solution for your specific needs:

- MIG Welding: Ideal for thicker materials and large-scale projects, MIG welding provides fast, efficient welding with strong, durable results. It’s perfect for production environments where speed and consistency are key.

- TIG Welding: Offering superior precision and control, TIG welding is ideal for thinner materials and applications where weld appearance and accuracy are critical. This method produces clean, high-quality welds with minimal spatter.

Contact Us Today for a Quote

At L&N Metal Works, we tailor our welding services to meet specific project requirements, from one-off custom pieces to high-volume production runs. Whether your project requires the speed of MIG welding or the precision of TIG welding, our AWS Certified welders deliver the highest quality results. Contact L&N Metal Works today to learn more about our welding services. From raw material to refined result – we make metal work. Request a quote today.

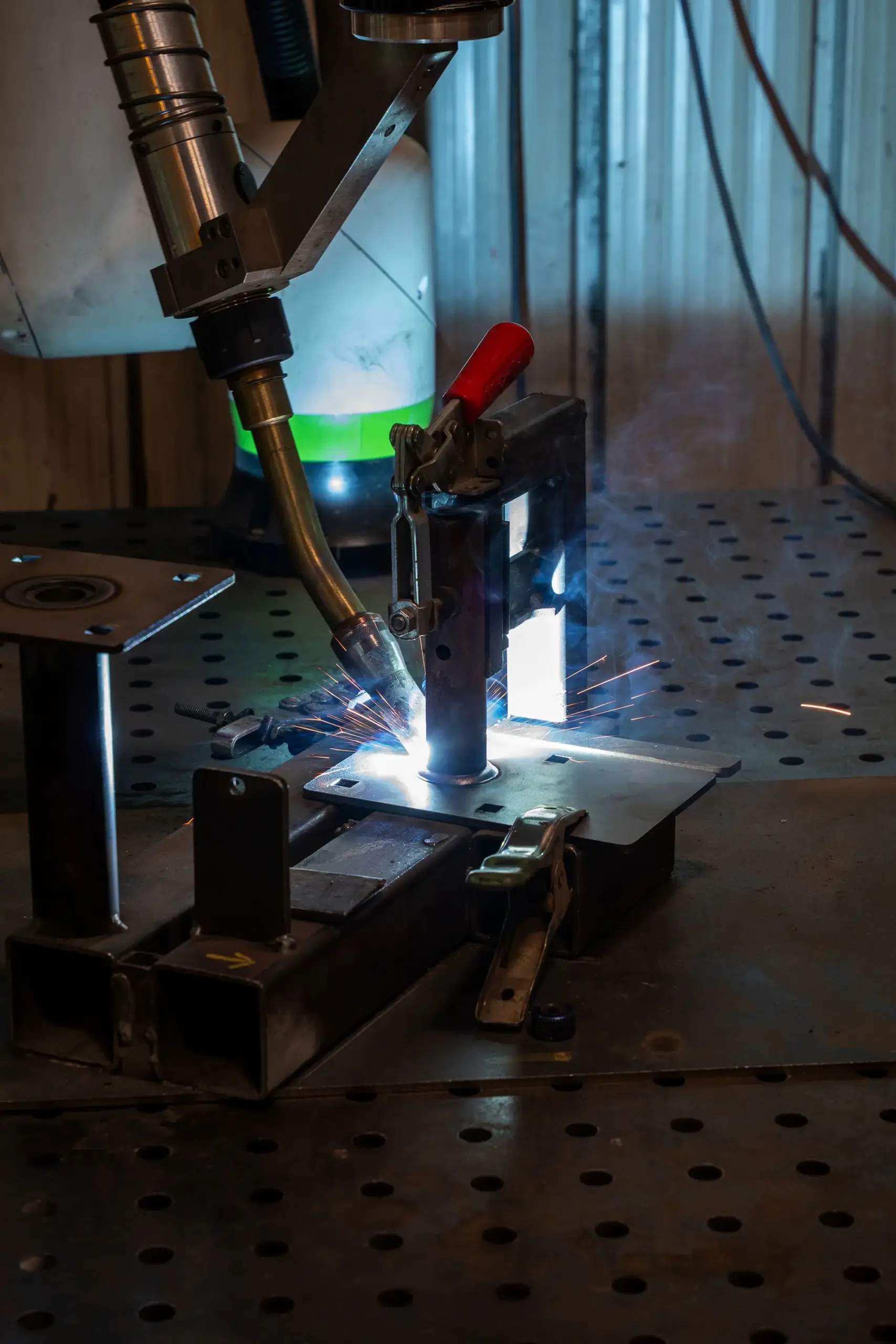

Robot Welder

When it comes to large-scale production runs, speed and efficiency are two of the keys to success. Manually welding 500 or more metal components is both time-consuming and labor intensive. Thus, companies rely on automation to achieve better, faster results. By leveraging the latest robot welding technology, L&N Metal Works streamlines the welding process, allowing for faster production times without compromising on quality. The efficiency of L&N Metal Works’ Robot Welder translates into cost savings, particularly for large production runs or complex welding jobs.

Capabilities of Robot Welding

L&N Metal Works’ robot welder handles complex welding tasks with remarkable accuracy and repeatability. Key features include:

- Automated Precision: The robot welder ensures consistent weld quality, reducing the risk of human error and ensuring every weld meets exact specifications.

- Versatile Welding: Capable of handling a wide range of materials, including steel, stainless steel, and aluminum, across various thicknesses and configurations.

- Collaborative Technology: The robot’s collaborative nature allows it to work safely alongside human operators, enhancing productivity and flexibility in the welding process.

Contact Us Today for a Quote

L&N Metal Works’ robot welder works alongside human operators to maintain weld quality, weld production, process repeatability, and worker safety. When your team needs fast, consistent, and precise welds for large-scale production, L&N Metal Works is ready to help. Contact us today to learn more about Robot Welding. From raw material to refined result – we make metal work. Request a quote today.

Surface Finishing

Vibratory Finishing Machine

At L&N Metal Works, finishing is more than a final step. It’s a critical part of delivering clean, consistent, and production-ready components. Our vibratory finishing machine provides high-capacity vibratory tumbling for small to mid-sized metal parts, ensuring smooth edges, refined surfaces, and reduced handling risks. Components are ready for your next step in production or delivery.

Capabilities of Vibratory Finishing Machine

L&N Metal Works’ Vibratory Finishing Machine meets the demand for clean, fast, and efficient finishing. Key capabilities include:

- Deburring & Edge Smoothing: Removes sharp edges and burrs from stamped, cut, or machined parts.

- Surface Conditioning: Prepares parts for coating, welding, or assembly with uniform finishes.

- Batch Processing: Efficiently handles multiple parts with consistent results across runs.

- Media Versatility: Compatible with ceramic, plastic, and other abrasive media tailored to your material and finish requirements.

Contact Us Today for a Quote

L&N Metal Works’ high-capacity vibratory tumbling ensures metal components have a clean finish. Whether you’re finishing brackets, fittings, or small assemblies, our vibratory tumbler delivers consistent quality with minimal distortion. Contact us today to learn more about our vibratory finishing machine. From raw material to refined result – we make metal work. Request a quote today.

Deburring and Finishing Machine

At L&N Metal Works, precision doesn’t stop at fabrication. It extends to the final finish. Our 52″ wide, four-head dry deburring and finishing machine delivers high-performance deburring, grinding, edge rounding, and straight grain finishing. This machine allows us to process large panels and high-volume parts with speed and consistency. The deburring and finishing machine delivers smooth edges, clean surfaces, and ready-to-coat finishes.

Capabilities of Deburring and Finishing Machine

L & N Metal Works’ Deburring and Finishing Machine streamlines edge finishing. Key capabilities include:

- Deburring: Removes sharp edges, slag, and dross from laser-cut parts.

- Edge Radiusing: Applies uniform edge rounding for improved safety, coating adhesion, and part handling.

- Surface Conditioning: Produces straight grain finishes and prepares parts for painting, powder coating, or assembly.

- Multi-Head Flexibility: Four-head configuration allows for sequential processing in a single pass.

Contact Us Today for a Quote

Deburring is a critical step in the metal finishing process, improving the quality, safety, and performance of metal components. L & N Metal Works’ deburring and finishing machine readily handles high volume orders and large panels, delivering consistent, production-ready results. Contact us today to learn more about our deburring and finishing machine. From raw material to refined result – we make metal work. Request a quote today.

Traditional Craftsmanship & Advanced Fabrication

Today, L&N Metal Works blends traditional craftsmanship with advanced fabrication technology. Every upgrade has been driven by a commitment to quality, efficiency, and the evolving needs of our clients. From custom metalwork to large-scale production, we continue to build on the legacy that started with a father, a son, and a shared passion for welding. Contact us for a quote for custom metal fabrication, architectural steel, and structural steel framing projects in the Midwest and across the U.S.